Quality Assurance

Here at our plant, we follow all the precautions related to food and safety standards. Our SAP – S4 Hana implemented manufacturing facility is well equipped with ultra-modern machinery. Our manufacturing plant is BRCGS Certificated, which makes it one of the best packaging material manufacturing facilities of the country.

Over the years, Knack Packaging has become the synonym of quality. We believe in providing the highest quality of bags to our clients. To maintain excellence in our products, we follow a stringent quality control process at our end, from the procurement of raw material to packaging that goes until the final delivery of products. We have specialized quality checks in every department apart from a centralized quality check department. Our team of quality controllers monitors the processing methods and supervises all the processes efficiently to maintain quality in our range. With the help of our quality controllers, we have a unique feature of bag inspection. We inspect them through six steps to check various parameters ranging from the fabric to the printing errors.

We believe that quality surpasses everything else. It is the very first thing that you notice in anything. With the help of our vast experience in the industry, we fulfil our promise of topnotch quality in every single product. To do that efficiently, we leave no stones unturned and have set up a facility where we quality check even the smallest of raw materials used in making our products. The result of the whole process is the ultimate satisfaction of our clients in terms of high-end quality and longevity of our products.

Certifications

SAP S/4HANA

It is a future-ready enterprise resource planning (ERP) system with built-in intelligent technologies, including AI, machine learning, and advanced analytics. It transforms business processes with intelligent automation and runs on SAP HANA – a market-leading in-memory database that offers real-time processing speeds and a dramatically simplified data model.

A predefined set of mandatory steps which are to be followed while processing an order, ensures zero error functioning. It covers everything right from raw material procurement to delivery of final goods and enables our customers to focus on their business without worrying about packaging material.

EcoVadis Bronze Medal

EcoVadis medals recognize companies that have completed the EcoVadis assessment process and demonstrated a relatively strong management system that addresses sustainability criteria, as outlined in the EcoVadis methodology. Companies must also meet specific licensing and eligibility criteria. The EcoVadis Rating covers a broad range of non-financial management systems including Environmental, Labor & Human Rights, Ethics and Sustainable Procurement impacts. Each company is rated on the material issues as they pertain to their company's size, location and industry. To drive global supply chain sustainability, large multinational corporations partner with EcoVadis, leveraging the influence of spend as a "force for good" to push trading partners beyond compliance. The rated company can see how their score compares to the benchmark in their industry. Combining the scorecard results with improvement areas results in a "race to the top," in which whole industries compete to achieve global best practice.

International standards

The BRCGS for Packaging Materials was designed to protect the consumer by providing a common basis for the certification of companies supplying packaging to food producers. The BRCGS now provides a robust framework for all types of packaging manufacturer to assist them in the production of safe packaging materials and to manage product quality to meet customers’ requirements, while maintaining legal compliance.

The format is designed to allow a company’s premises, operational systems and procedures to be assessed against the requirements of the Standard by a certification body.

ISO 14001:2015

ISO 14001:2015 is the global standard for environmental management systems. It helps organizations improve environmental performance through efficient resource use and waste reduction. ISO 14001 defines an aspect as an "element of an organization's activities, products or services that interacts or can interact with the environment" and an impact as a "change to the environment, whether adverse or beneficial, wholly or partially resulting from an organization's environmental aspects."

ISO 9001:2015

ISO 9001:2015 sets the international benchmark for quality management systems. It ensures consistent product quality and customer satisfaction through principles like customer focus and continual improvement. ISO 9001 was developed from a number of quality management principles including a strong customer focus, relationship management, the influence of top management, and continual improvement.

ISO 45001:2018

ISO 45001:2018 outlines requirements for Occupational Health and Safety (OH&S) management systems. It aids in creating safe workplaces by preventing work-related injuries and illnesses. Our Organization is ISO 45001 certified which helps us to reduce hazardous environments in the workplace.

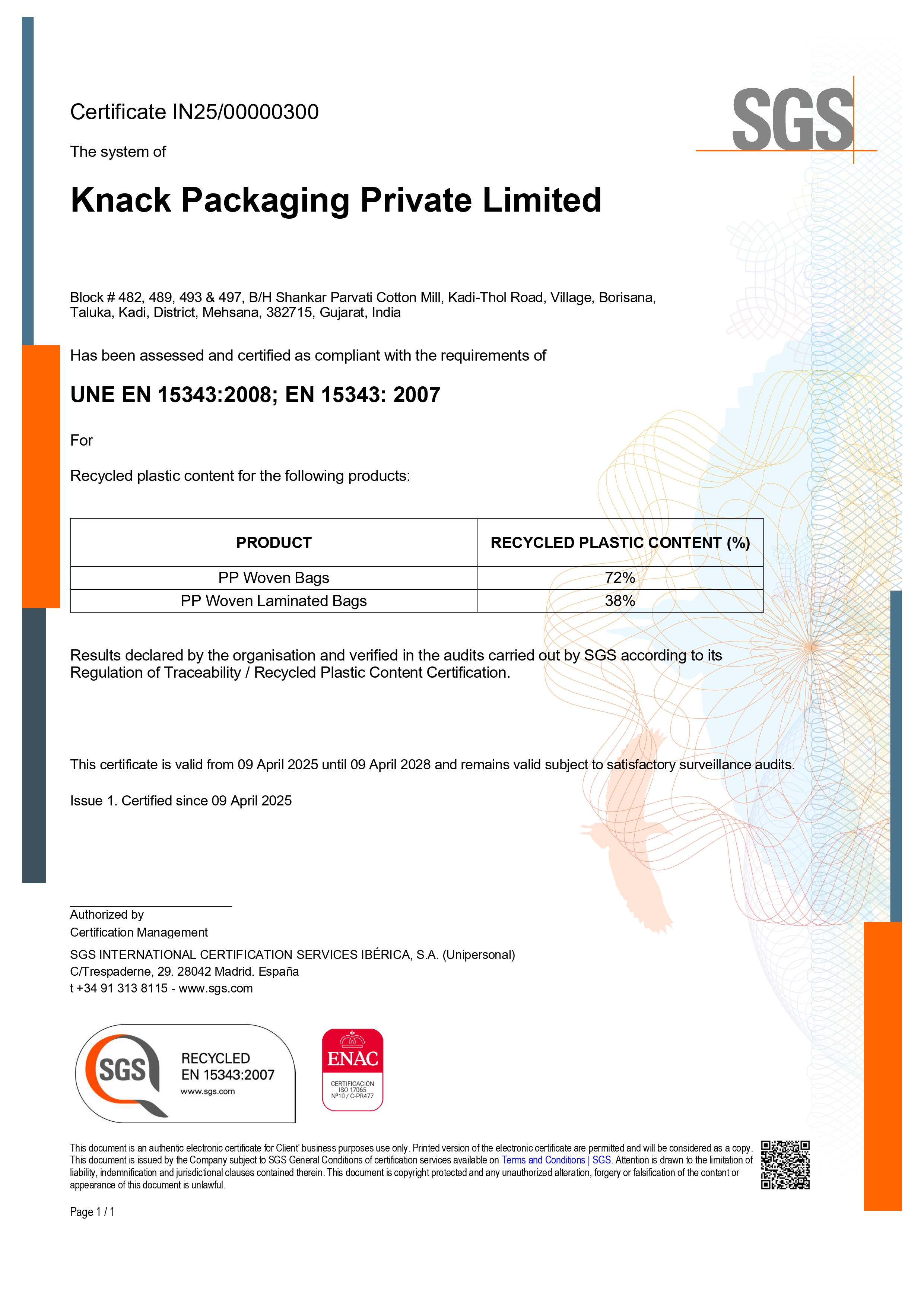

European Standards for Traceability and Conformity Assessment of Recycled Plastics.

Knack Packaging holds full certification under EN 15343:2007 and EN 15343:2008, the European standards for traceability and conformity assessment of recycled plastics. This accreditation covers every stage from post-consumer feedstock intake through to finished product with independent audits ensuring transparent control of material flows and verification of recycled-content claims. Within this certified system, our PP Woven Bags contain 72% mechanically recycled polypropylene, and our PP Woven Laminated Bags incorporate 38% recycled content. We partner with accredited recyclers and maintain stringent in-process controls, including spectroscopic analysis and melt-flow testing, to ensure that performance matches virgin-grade equivalents. Maintaining EN 15343 certification underscores our dedication to sustainable manufacturing and circular-economy principles. It provides customers with verifiable environmental credentials and drives ongoing investments in advanced recycling technologies to raise recycled-content thresholds and further reduce our carbon footprint.

Looking for Professional Approach and Quality Services ?

At Knack Packaging, it’s all about giving the clients the best quality products