HOT STAMPING | RFID (Radio Frequency Identification) | Barcode | QR Code

In today’s highly competitive and brand-conscious market, implementing robust security systems like RFID, QR codes, barcodes, and hot stamping has become not just a value addition but a necessity for our packaging operations.

As a packaging company catering to premium and branded clients, these technologies play a critical role in safeguarding brand integrity, ensuring traceability, and enhancing supply chain transparency.

Duplicity is a growing threat that undermines consumer trust, devalues genuine products, and exposes brands to significant reputational and financial risks, hence we serve as a strong protection against duplicity in our packaging through these security features.

Hot Stamping

Hot Stamping is a physical printing method that uses heat,pressure, and a metal or holographic foil to imprint designs,logos, or security features onto packaging materials. The metallic or holographic effect not only adds a premium look but also acts as a tamper-evident seal and avoid duplicity making it difficult for many imposters to replicate. It is often used to emphasize brand logos, limited edition packaging, and security seals.

Hot stamping is versatile, compatible with various substrates, and does not require drying time, making it a clean and efficient process suitable for high-speed production lines. Additionally, the durability of hot-stamped finishes ensures the design remains intact and untarnished throughout the product’s lifecycle.

Brand Differentiation

Premium Look and Feel

Authenticity

Avoid Fraudsters

Aesthetic Enhancement: Offers a visually striking finish (e.g., gold, silver, holographic) that enhances brand perception and shelf appeal.

Security Feature: Incorporates holographic foils or unique patterns that are hard to replicate, making it a strong fraud detection measure.

Durability: Resistant to fading, scratching, and wear, ensuring long-lasting brand presence on the package.

Brand Identity: High-end brands use hot stamping to signal quality and avoid duplicity.

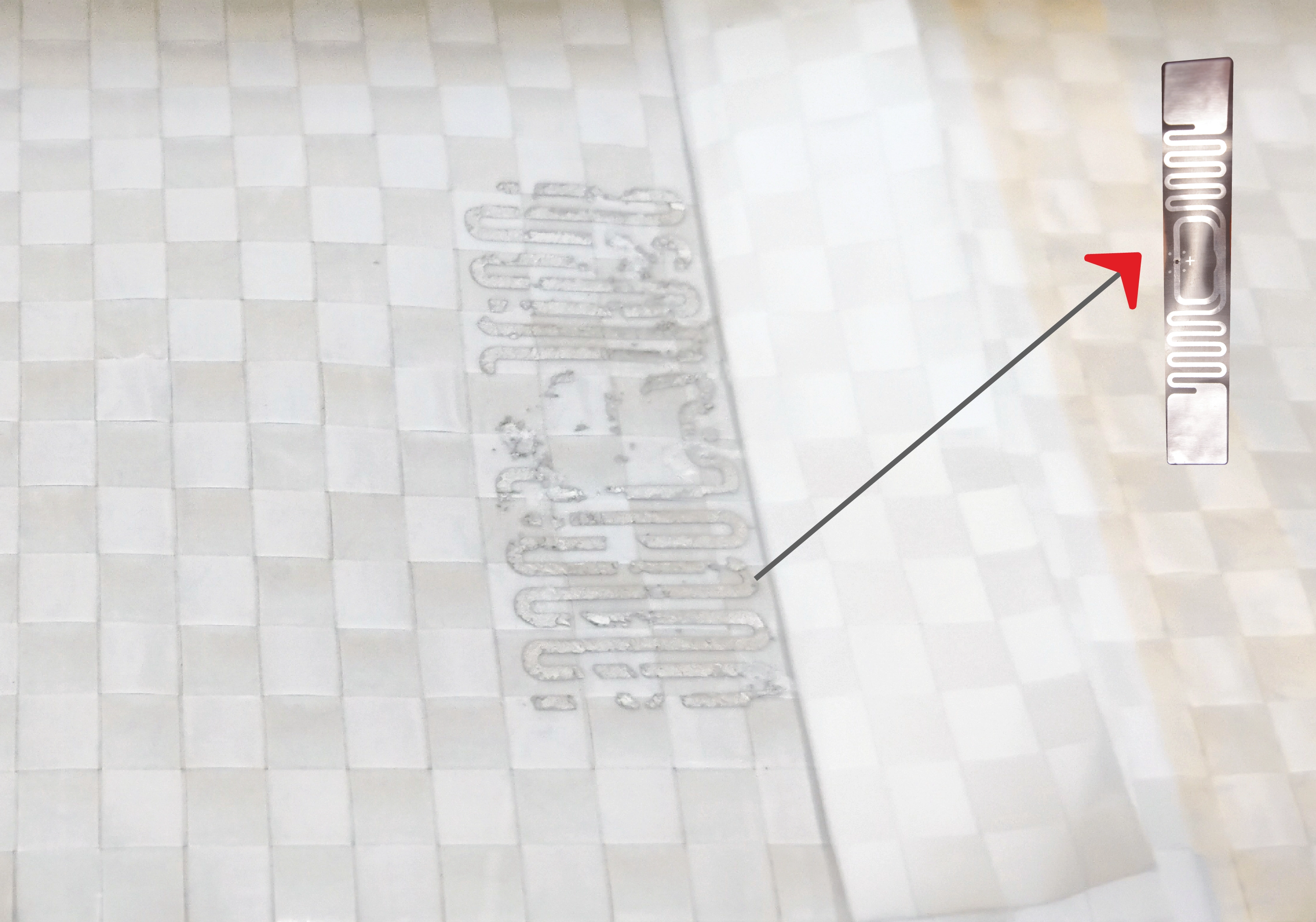

RFID (Radio Frequency Identification)

RFID is a wireless technology that uses electromagnetic fields to identify and track tags attached to the packaging. RFID plays a vital role for inventory management, tracking material and ensuring product visibility. It helps the vendor and their distributor to see the exact stock of a specific variant or the bulk quantity and before any shortage will be ordered accordingly.

RFID tags can hold a significant amount of product-specific data,making them ideal for branded clients who demand full traceability and supply chain transparency.

Real Time Tracking

Improved Inventory Management

Enhanced Customer Experience

Sustainability

Real-Time Tracking: Continuous monitoring of goods through production to retail.

Bulk Scanning: IScan hundreds of items simultaneously without line-of-sight.

Data Capacity: Holds product-specific data like batch, origin, and expiry.

Automation Friendly: Integrates with smart logistics and automated warehousing.

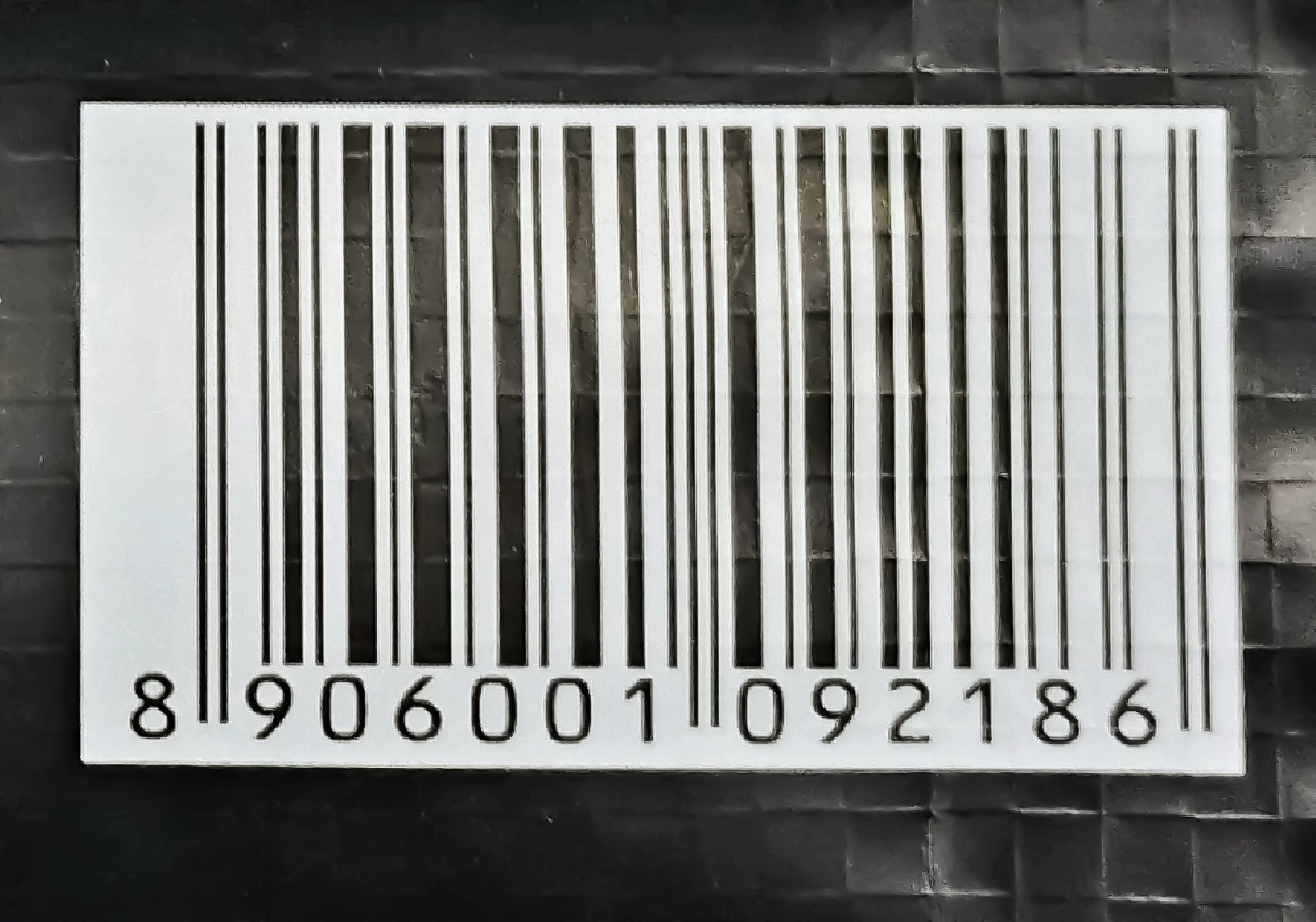

Barcode

A Barcode is a one-dimensional (1D) optical representation of data, usually in the form of parallel black lines of varying widths and spacing. Each barcode corresponds to a numeric or alphanumeric code that is stored in a database. It is the most widely used identification tool in branded flexible packaging industry and supply chain systems.

They are highly efficient for tracking items during packaging, labelling, inventory control, and retail sales. If during any process there is any tampering or damage it will help track the production lot and details. For clients focused on efficient distribution and inventory tracking, barcodes remain a reliable solution.

Fast and Accurate Product Identification

Inventory Management

Cost Effective and Easy to Implement

Product Traceability

Simplicity: Quick to generate, scan, and apply using basic tools.

Cost-Effective: Very low cost to print and integrate.

Speed & Efficiency: Speeds up sorting, shipping, and sales processes.

Universal Adoption: Accepted worldwide in logistics and retail systems.

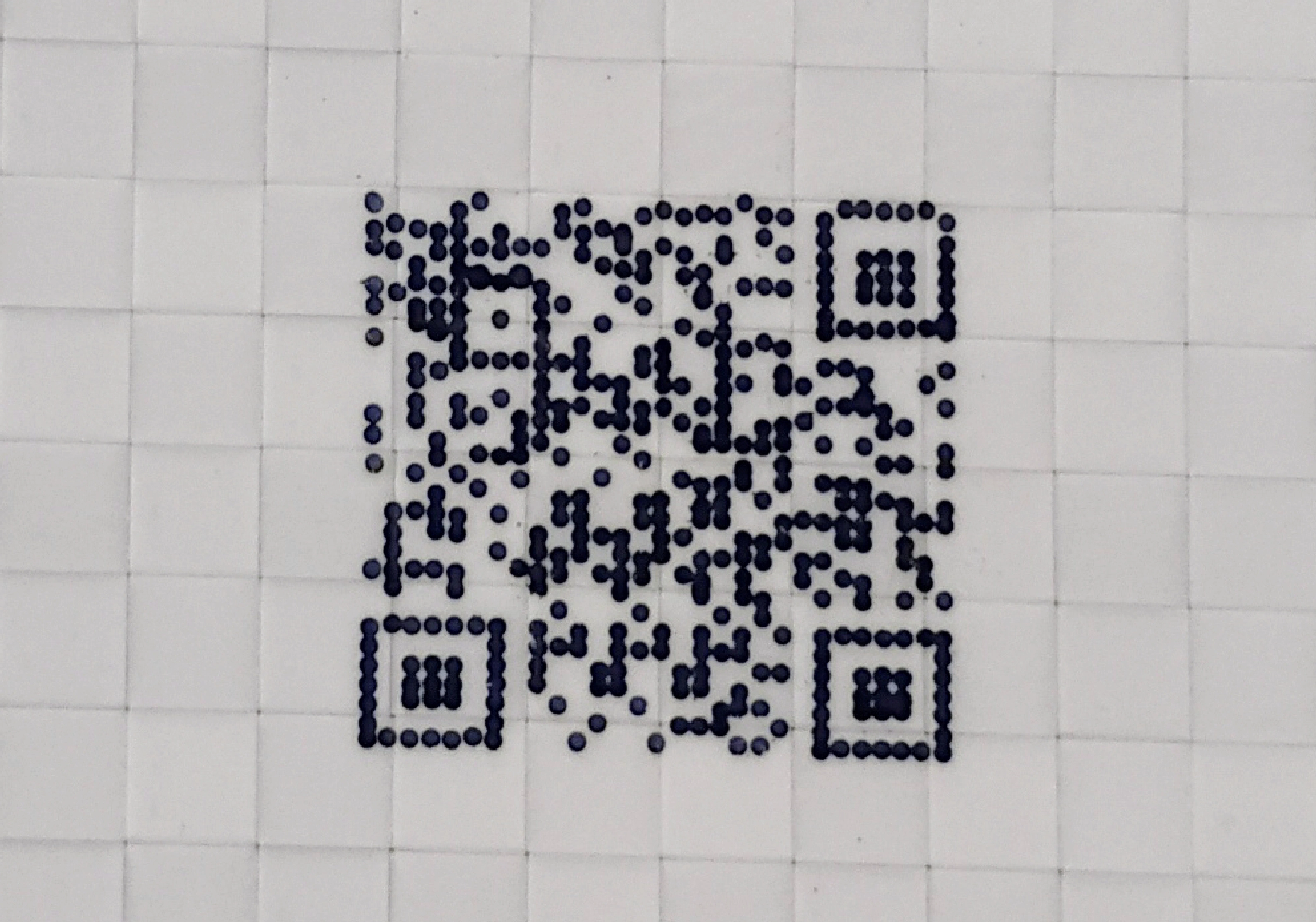

QR Code

QR Code can store much more information than traditional barcodes, such as product details, URLs, batch numbers, or interactive content. They can be scanned easily with smartphones or QR readers, making them ideal for consumer-facing packaging.

QR codes enable a brand to offer added value, such as linking customers to product videos, authenticity checks, promotions, or instructions. For branded customers, this technology enhances customer engagement and digital traceability to show how the product was made and their authenticity, helping bridge trust between the company and consumer in branded flexible packaging industry.

Enhanced Consumer Engagement

Product Authentication

Space Saving and Versatile

Real Time Traceability

High Data Capacity: Can store over 4,000 alphanumeric characters, including web links, product info, manuals, authentication keys, etc.

Consumer Interaction: Easily scanned using mobile phones, making them ideal for linking consumers to digital experiences like videos, tutorials, promotions, or product authenticity pages.

Compact & Flexible: Can be printed in small spaces and still retain all stored information.

Traceability: Helps track products through the supply chain when paired with databases.

Marketing Tool: Brands use QR codes to collect user data, offer personalized experiences, and drive online traffic.

User Accessibility: QR codes enhance user accessibility in the packaging industry by providing instant access to product information, instructions, and digital services with a simple smartphone scan.